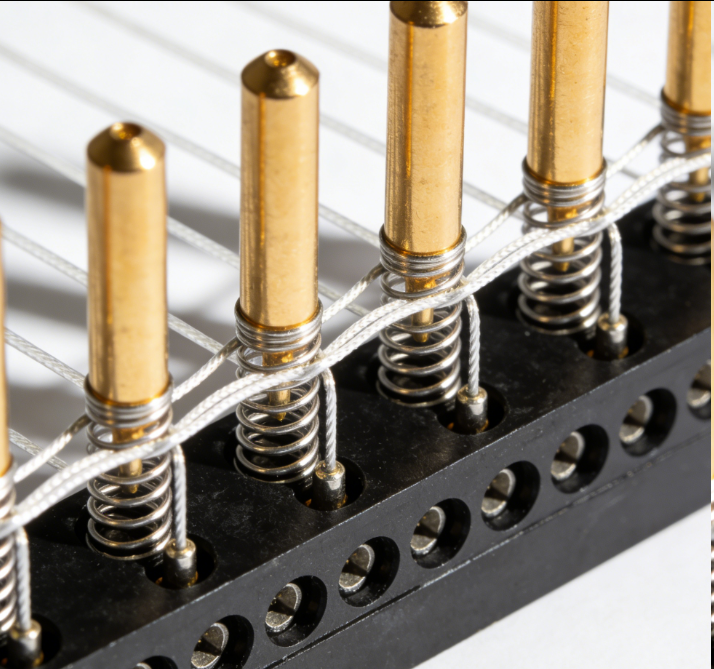

The pin diameter of pogopin probes is a critical parameter that significantly influences their performance, functionality, and suitability for various applications. Pogopin probes, also known as spring - loaded pins, are widely used in electronic devices

The load - bearing capacity of Pogopin Probes is a fundamental characteristic that determines their suitability for different electrical connection applications. This capacity refers to the maximum mechanical and electrical loads that a pogopin probe ca

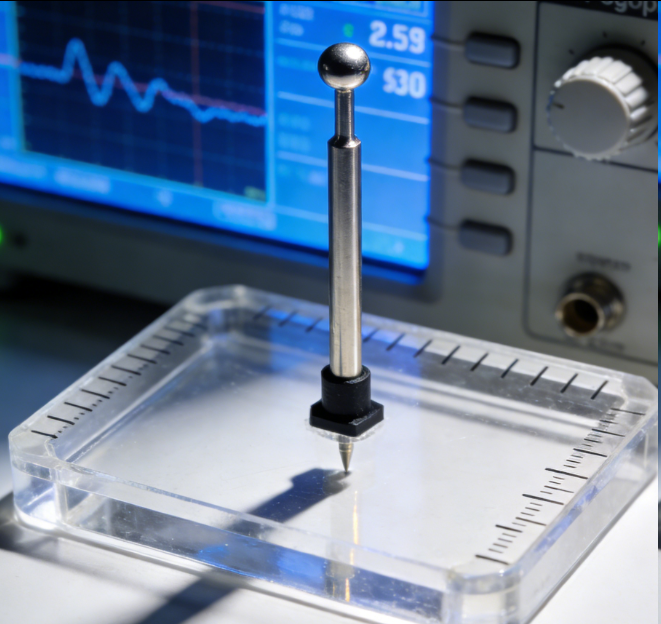

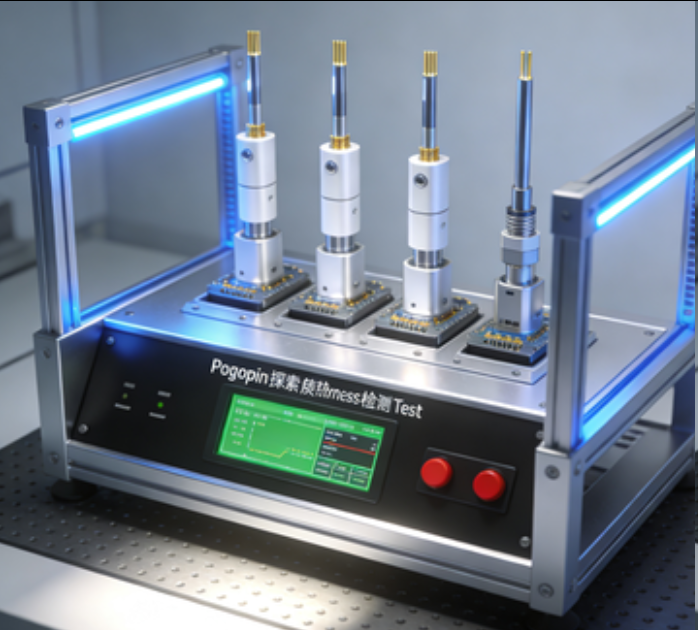

Fatigue resistance testing of Pogopin Probes is a critical process that evaluates the ability of these components to withstand repeated mechanical and electrical stresses over an extended period. Pogopin probes are subjected to cyclic loading during the

The choice of electrode materials for pogopin probes is a critical factor that significantly influences their electrical performance, durability, and overall reliability. Pogopin probes are used in a wide variety of applications, from consumer electronics

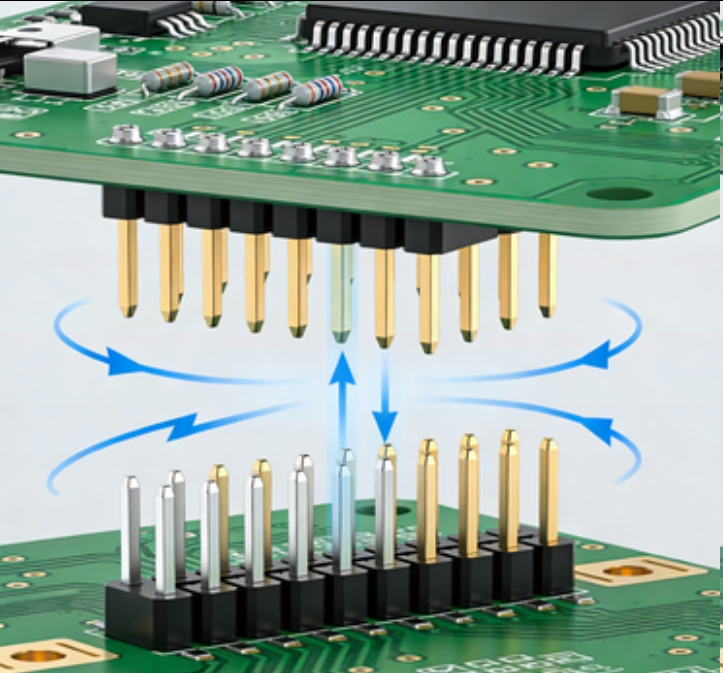

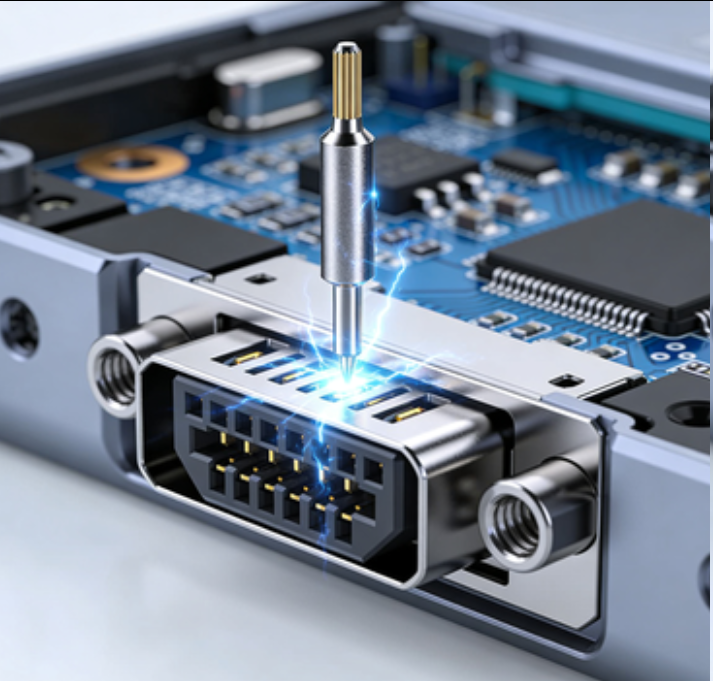

Pogopin probes, also known as spring - loaded pins, play a crucial role in electrical connection systems, offering reliable and efficient solutions for a wide range of applications. These probes are designed to establish electrical contact between two com

Salt spray resistance testing is a crucial evaluation for pogopin probes, especially for those deployed in harsh environments such as coastal areas, marine equipment, and some industrial settings with high humidity and salt - laden air. This testing metho

The contact reliability of pogopin probes is of paramount importance in ensuring the seamless operation of electronic devices. As these probes serve as crucial connectors for electrical signals, any compromise in their contact reliability can lead to inte

The oxidation resistance of pogopin probes is a critical property that significantly affects their long - term performance and reliability. Oxidation occurs when the metal surfaces of the probes react with oxygen in the air, forming oxide layers that can