Time:2025-05-23 Views:1 source:News

High-power equipment, such as industrial machinery, electric vehicles, and renewable energy systems, places stringent requirements on the components used for electrical connections. High-current pogo pins designed for these applications must be engineered to meet the unique challenges associated with high-power transmission, including handling large currents, withstanding harsh environments, and ensuring reliable performance.

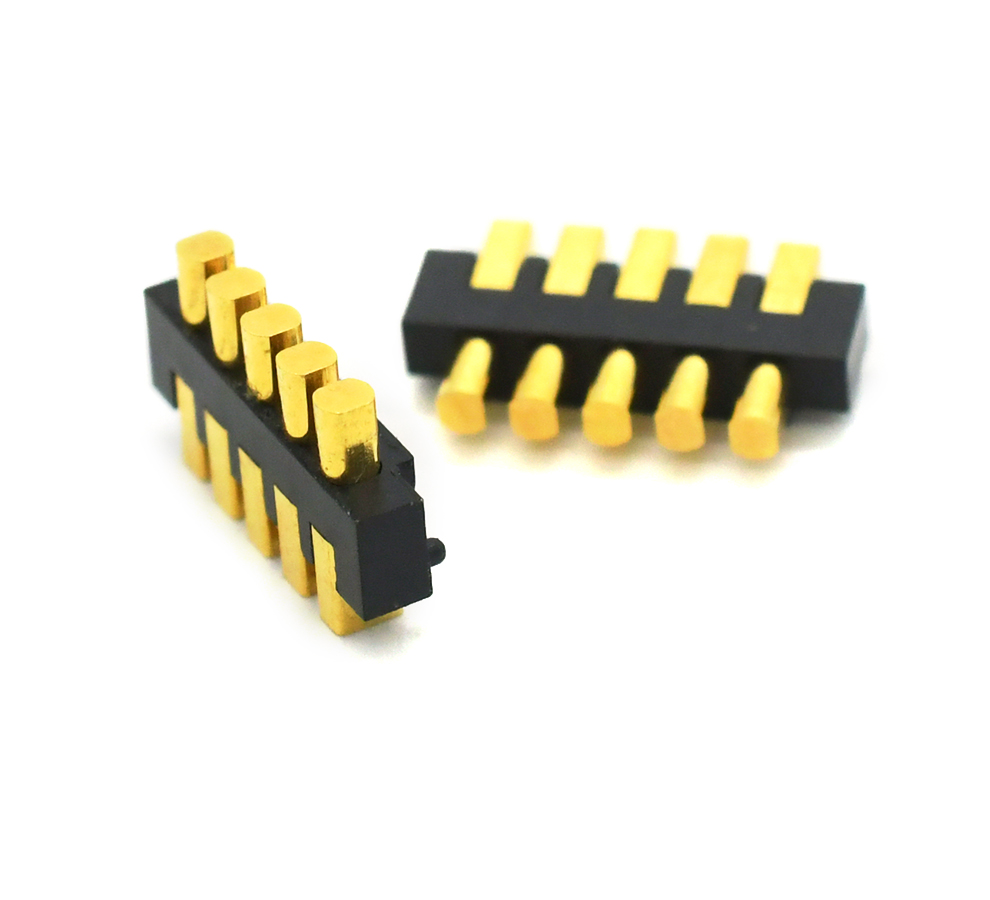

One of the primary requirements for high-current pogo pins in high-power equipment is the ability to carry substantial currents without overheating or failing. These pins need to have a robust design with large cross-sectional areas to reduce resistance and facilitate efficient current flow. Specialized materials with high electrical conductivity and thermal conductivity are often employed to manage the heat generated by high currents. For example, copper-based alloys with enhanced thermal dissipation properties may be used for the pin body and barrel, while advanced plating techniques can further optimize the electrical contact surfaces.

High-power equipment often operates in demanding environments, including high temperatures, humidity, dust, and vibration. High-current pogo pins must be designed to withstand these conditions. Sealed designs are commonly used to protect the internal components from moisture and contaminants, while rugged construction materials and reinforced mechanical structures help resist mechanical stresses and vibrations. Some high-current pogo pins for high-power equipment may also feature anti-corrosion coatings or encapsulation to ensure long-term reliability in harsh environments.

In addition to electrical and environmental requirements, high-current pogo pins for high-power equipment must offer ease of maintenance and replacement. In industrial settings, downtime can be extremely costly, so the pins should be designed for quick and easy installation and removal. Modular designs that allow for individual pin replacement without disassembling the entire connection system are highly desirable. Moreover, these pins should be compatible with a wide range of connectors and mating interfaces used in high-power equipment to ensure seamless integration.

Another important aspect is safety. High-current pogo pins in high-power equipment must comply with strict safety standards to prevent electrical hazards such as short circuits, arcing, and leakage. Insulated components, proper grounding mechanisms, and overcurrent protection features are often incorporated into the design to ensure the safe operation of the equipment and protect personnel from potential risks.

Read recommendations:

Magnetic PogoPin manufacturer price

Fast manufacturer of magnetic connectors