Time:2025-07-28 Views:1 source:News

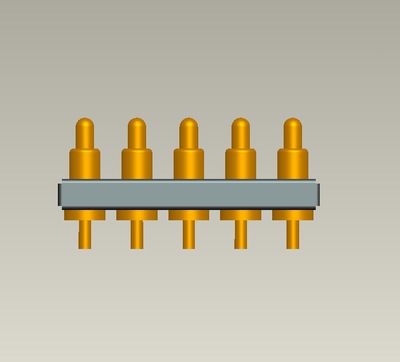

Selecting high - quality PogoPin connectors is crucial for ensuring reliable electrical connections in various electronic devices, from consumer electronics to industrial equipment. Given their wide - ranging applications, several key factors must be considered during the selection process.

1. Application - Specific Requirements

First and foremost, understanding the intended application is essential. Different applications have distinct demands. For example, in smartphones and wearables, where space is at a premium, compact and low - profile PogoPin connectors with a small pin pitch (as low as 0.3 - 0.4 mm in some advanced designs) are required. These connectors need to support high - speed data transfer (up to several Gbps for 5G - enabled devices) and handle the charging current efficiently (ranging from 1 - 10 A depending on the device’s battery capacity). In automotive applications, PogoPins must withstand harsh environments, including temperature variations from - 40°C to 125°C, high vibrations, and exposure to dust and moisture. They are used in charging systems, infotainment controls, and sensor diagnostics, often requiring high - current - carrying capacity (up to 50 A in some high - power charging scenarios) and a large number of mating cycles (up to 500,000 or more).

2. Electrical Performance

The electrical performance of PogoPin connectors is a critical aspect. This includes parameters such as current rating, voltage rating, and contact resistance. The current rating should be selected based on the maximum current the connector will need to carry. For example, a connector used in a high - power industrial motor control system may require a current rating of 20 - 30 A, while a connector for a small sensor module in a consumer device may only need to handle a few milliamperes. The voltage rating must also exceed the maximum voltage applied in the circuit to ensure safe operation. Contact resistance should be as low as possible (ideally less than 50 milliohms) to minimize power loss and heat generation during current flow. Low - resistance connectors are particularly important in high - current applications, as excessive heat can damage the connector and adjacent components.

3. Material Quality

The materials used in PogoPin connectors significantly impact their performance and durability. The pins are often made of materials like brass, beryllium copper, or tellurium copper. Brass offers good electrical conductivity and is cost - effective, but it may be less durable in harsh environments. Beryllium copper has excellent electrical and mechanical properties, including high fatigue resistance, making it suitable for applications with frequent mating and unmating cycles. Tellurium copper also provides good conductivity and enhanced machinability. The plating on the pins is equally important. Gold plating is highly desirable as it offers superior corrosion resistance, low contact resistance, and excellent electrical performance. However, it is relatively expensive. Nickel plating is more cost - effective but may not provide the same level of corrosion resistance as gold. In some applications where cost is a major concern but decent performance is still required, a combination of nickel - under - gold plating can be used.

4. Mechanical Durability

Mechanical durability is another key consideration. PogoPin connectors should be able to withstand the rigors of normal use, including vibration, shock, and repeated mating and unmating. The spring mechanism inside the connector is a critical component in this regard. High - quality springs are made of materials like stainless steel or phosphor bronze, which offer good elasticity and long - term fatigue resistance. The connector’s design should also ensure proper alignment during mating to prevent misalignment - related failures. For applications in portable devices that are frequently moved or dropped, connectors with shock - absorbing features or additional mechanical safeguards are preferred. Additionally, the number of mating cycles a connector can endure is an important metric. In industrial and automotive applications, connectors may need to support 100,000 - 500,000 mating cycles, while in consumer electronics, a minimum of 5,000 - 10,000 cycles is often expected.

5. Manufacturer and Supplier Reputation

Choosing a reputable manufacturer and supplier is essential. Reputable companies adhere to strict quality control processes during manufacturing. They conduct thorough testing, including electrical performance testing, mechanical durability testing, and environmental testing (such as temperature and humidity cycling). They also provide detailed product documentation, including datasheets that accurately specify the connector’s performance parameters. Customer reviews and feedback can be a valuable source of information. A manufacturer with a track record of delivering high - quality products and providing good customer support is more likely to offer reliable PogoPin connectors. Additionally, companies that are involved in industry - standard development and compliance are more likely to produce connectors that meet or exceed industry requirements.

By carefully evaluating these factors, one can select PogoPin connectors that offer optimal performance, reliability, and durability for their specific application needs.

Read recommendations: