Time:2025-10-17 Views:1 source:News

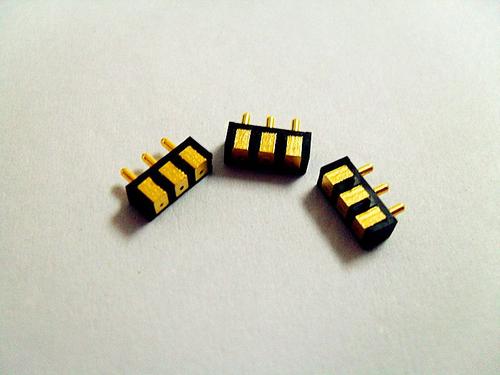

The rebound performance of pogopin probes is a critical factor that significantly influences their reliability and lifespan in various electronic applications. Pogopin probes, also known as spring - loaded pins, are widely used in electrical connections due to their ability to provide stable and reliable electrical contact. The rebound performance refers to the probe's capacity to return to its original position after being compressed, ensuring consistent contact pressure and electrical conductivity.

Several key elements determine the rebound performance of pogopin probes. The material of the spring inside the probe plays a pivotal role. High - quality spring materials, such as beryllium copper (BeCu) or stainless - steel alloys, are commonly used. Beryllium copper springs offer excellent elasticity, fatigue resistance, and electrical conductivity, enabling the probe to maintain its shape and performance even after numerous compression and release cycles. Stainless - steel springs, on the other hand, provide superior corrosion resistance, making them suitable for harsh environments. The design of the spring, including its wire diameter, pitch, and number of coils, also affects the rebound performance. A well - designed spring with an appropriate balance of these parameters can ensure sufficient force for reliable contact while maintaining good rebound characteristics.

Testing the rebound performance of pogopin probes is essential to guarantee their quality. One common testing method involves using a force - displacement testing machine. The probe is compressed to a specific displacement, and the force required for compression and the force during the return stroke are measured. By analyzing the force - displacement curve, engineers can evaluate the probe's rebound efficiency, hysteresis (the difference between the compression and return forces), and overall spring performance. Another approach is to subject the probes to a specified number of compression - release cycles and then measure any changes in the contact resistance or mechanical dimensions. A significant increase in contact resistance or deformation of the probe indicates a decline in rebound performance.

In practical applications, a pogopin probe with good rebound performance ensures stable electrical connections. For example, in battery connectors of mobile devices, consistent rebound allows the probe to maintain a firm connection with the battery contacts, preventing intermittent power supply issues. In high - density circuit board testing, reliable rebound performance enables accurate and repeatable electrical testing, reducing the likelihood of false readings due to poor contact. Therefore, optimizing the rebound performance of pogopin probes is crucial for enhancing the overall performance and reliability of electronic products that rely on these components.

Read recommendations:

Pogo Pin Connector for Automation Equipment

New supplier of CCS1 to Tesla adapter