Time:2025-07-25 Views:1 source:News

Large amusement rides, such as roller coasters, Ferris wheels, and interactive simulators, rely on high-current spring pins (Pogo Pins) to ensure reliable power transmission and signal communication in demanding operational environments. These rides often feature moving components, rotating cabins, or dynamic interfaces that require robust electrical connections capable of handling high currents while withstanding constant vibration, mechanical stress, and environmental factors like dust and moisture.

High-current spring pins designed for amusement rides are engineered to carry currents ranging from 50A to 200A, depending on the power requirements of components such as motors, lighting systems, and control panels. Their spring-loaded design allows for axial compression, ensuring consistent contact even when there is relative movement between connected parts—critical for rotating sections of Ferris wheels or articulating joints in roller coaster cars. This flexibility prevents connection interruptions that could lead to operational failures or safety hazards.

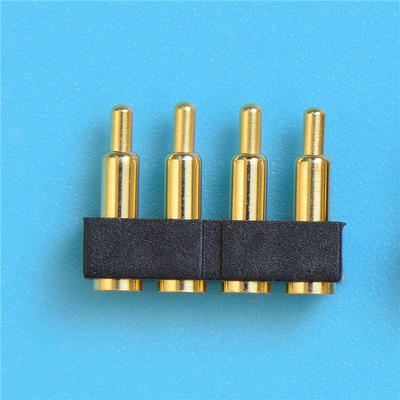

Material selection is crucial for these pins. They are typically constructed with high-conductivity metals like copper alloys plated with gold or nickel to minimize resistance and enhance corrosion resistance. The springs are made from durable materials such as stainless steel, ensuring they can withstand millions of cycles without fatigue. Additionally, the housing of these pins is often sealed to IP65 or higher standards, protecting internal components from water ingress and dust accumulation, which is essential for outdoor rides exposed to rain or debris.

Installation in amusement rides often involves integrating the pins into rotating interfaces or detachable sections, such as the connection between a ride’s stationary base and a moving cabin. This allows for quick disassembly during maintenance while ensuring a secure connection during operation. By providing stable high-current transmission and reliable signal integrity, these spring pins contribute to the safety and efficiency of large amusement rides, ensuring uninterrupted operation even under the most rigorous conditions.

Read recommendations:

Magnetic PogoPin factory customization

High speed signal Magnetic PogoPin